What Causes Concrete to Fail Early? A Technical Breakdown for Homeowners

Concrete is one of the most durable building materials available, yet many homeowners in Frisco discover cracks, spalling, or complete failure in their driveways, patios, and foundations far sooner than expected. Understanding why concrete fails prematurely can save you thousands of dollars in repairs and help you make informed decisions when planning your next concrete project.

Poor Mix Design: The Foundation of Failure

The concrete mixture itself is often the culprit behind early deterioration. When contractors cut corners by using incorrect water-to-cement ratios, the resulting concrete becomes weaker and more porous. Excess water makes the mix easier to work with, but it dramatically reduces the final strength of the cured concrete.

Additionally, using insufficient cement content or low-quality aggregates compromises the structural integrity from the start. The aggregates, sand and gravel make up about 60-75% of concrete volume, and when these materials contain impurities, clay, or organic matter, they prevent proper bonding and create weak points throughout the slab.

Inadequate Site Preparation

Even the best concrete mix will fail if poured over improperly prepared ground. The subbase must be compacted, level, and well-drained to provide uniform support. When soil beneath concrete isn't properly compacted, settling occurs unevenly, creating stress points that lead to cracking.

In Frisco, our expansive clay soils present unique challenges. These soils expand when wet and contract during dry periods, creating movement beneath concrete surfaces. Without proper excavation depth and a stable aggregate base, this soil movement translates directly into concrete failure. Professional contractors understand that adequate site preparation isn't optional; it's the difference between concrete that lasts decades and concrete that fails within years.

Improper Curing Practices

Curing is the process that allows concrete to achieve its designed strength, yet it's frequently rushed or neglected entirely. Concrete needs moisture and appropriate temperatures for at least seven days to properly hydrate and harden. When contractors remove forms too early, fail to keep the surface moist, or pour during extreme temperatures, the concrete never reaches its full potential strength.

During hot summer months, rapid moisture evaporation from the concrete surface causes plastic shrinkage cracks before the concrete even fully hardens. Conversely, pouring concrete when temperatures drop below 40°F slows the hydration process dramatically and can result in freeze damage before the concrete gains sufficient strength.

Insufficient or Improper Reinforcement

Concrete excels under compression but performs poorly under tension. Steel reinforcement addresses this weakness, but only when installed correctly. Control joints, rebar placement, and wire mesh positioning all play critical roles in managing stress and preventing crack propagation.

Many failed concrete slabs show evidence of missing or improperly positioned reinforcement. Rebar placed too shallow or too deep loses effectiveness. Control joints cut too shallow or spaced too far apart fail to direct cracking to predetermined locations. When working with Steadfast Concrete, homeowners receive properly engineered reinforcement that accounts for the specific application and local soil conditions.

Overloading and Improper Use

Concrete driveways and slabs are designed for specific load capacities. Parking heavy commercial vehicles, construction equipment, or RVs on residential concrete designed only for passenger vehicles creates stress beyond the original design parameters. Point loads from trailer jacks or concentrated weight from dumpsters can punch through concrete that would otherwise perform adequately under distributed loads.

The thickness of your concrete matters tremendously. A standard 4-inch residential driveway cannot support the same loads as a 6-inch commercial-grade installation. Before using your concrete surfaces for purposes beyond their original design, consult with professionals who can assess whether the existing installation can handle the additional stress.

Environmental Factors and Chemical Exposure

Freeze-thaw cycles represent one of nature's most destructive forces against concrete. Water penetrates small pores and cracks in the concrete surface, then expands approximately 9% when it freezes. This expansion creates internal pressure that progressively damages the concrete matrix. While Frisco experiences less severe freeze-thaw cycling than northern climates, periodic winter freezes still impact concrete longevity.

Chemical exposure accelerates concrete deterioration significantly. De-icing salts, though less commonly needed in Frisco, draw moisture into concrete through osmotic pressure while chemically reacting with calcium hydroxide in the cement paste. Petroleum products, fertilizers, and acidic substances also degrade concrete surfaces over time. Homeowners should clean spills promptly and avoid using harsh chemicals directly on concrete surfaces.

Poor Drainage and Water Management

Water is concrete's enemy in multiple ways. Standing water on concrete surfaces accelerates weathering and promotes the freeze-thaw damage discussed earlier. More critically, water that accumulates beneath concrete slabs erodes the subbase support and creates voids. As the underlying support disappears, concrete spans gaps it wasn't designed to bridge, leading to cracking and eventual failure.

Proper grading around concrete installations directs water away from the surface. Downspouts should discharge at least six feet from concrete slabs, and the surrounding landscape should slope away from structures. When you contact Steadfast Concrete at (214) 833-6372, their team evaluates drainage patterns as part of every project assessment to ensure long-term performance.

Lack of Preventive Maintenance

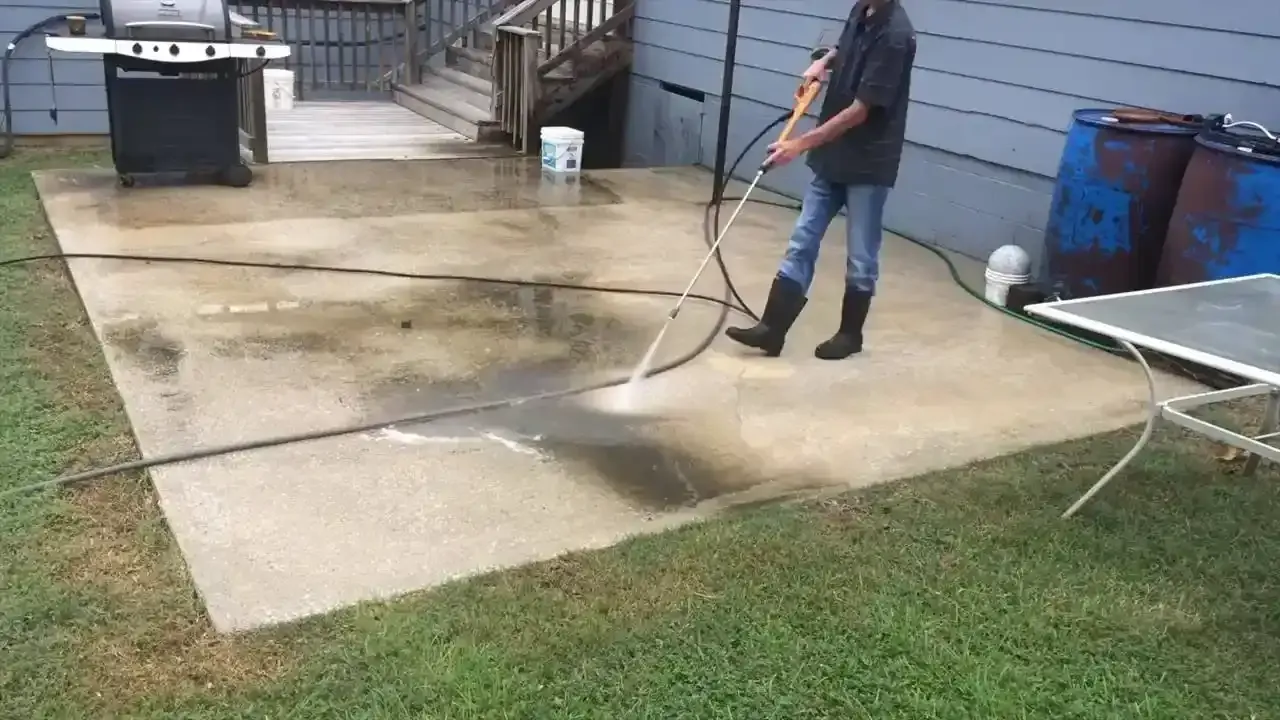

Even properly installed concrete requires ongoing maintenance to maximize its lifespan. Sealing concrete surfaces every 2-3 years creates a protective barrier against moisture penetration, chemical exposure, and surface wear. Small cracks that appear should be cleaned and filled promptly before they expand and allow water infiltration beneath the slab.

Regular cleaning removes substances that degrade concrete and allows you to spot developing problems early. A simple annual inspection can identify issues while they're still minor and inexpensive to address. Neglecting these simple maintenance tasks often transforms manageable concrete repairs into complete replacement projects.

Working with Qualified Contractors

The quality of installation dramatically impacts concrete longevity. Experienced concrete contractors understand local soil conditions, proper mix designs, adequate reinforcement requirements, and correct installation procedures. They don't cut corners on site preparation, they use appropriate equipment, and they follow industry best practices for curing.

Steadfast Concrete in Frisco brings technical expertise and quality materials to every project. Rather than risking premature failure with unqualified installers, homeowners benefit from working with contractors who understand the engineering principles behind durable concrete construction. You can reach their team at (214) 833-6372 to discuss your project and receive a professional assessment.

Protect Your Investment with Professional Concrete Installation

Don't let your concrete project become another premature failure statistic. Whether you're planning a new driveway, patio, foundation, or decorative concrete feature in Frisco, the expertise of your contractor makes all the difference. Steadfast Concrete combines proven installation techniques, quality materials, and thorough site preparation to deliver concrete that stands the test of time.

Ready to discuss your concrete project with professionals who prioritize longevity and quality? Call (214) 833-6372 today for a free consultation and estimate. Our experienced team will assess your property, explain your options, and provide honest recommendations tailored to your specific needs and budget. Don't settle for concrete that fails in five years when you could have a beautiful, durable installation that lasts for decades.

Frequently Asked Questions

How long should properly installed concrete last?

With professional installation and regular maintenance, concrete driveways and patios should last 30-50 years or more. Foundation concrete can last even longer when properly designed and installed. The lifespan depends heavily on initial quality, environmental conditions, usage patterns, and maintenance practices.

What are the first signs that my concrete is failing?

Early warning signs include hairline cracks, surface scaling or flaking, discoloration, minor settlement creating uneven surfaces, and water pooling in areas that previously drained properly. Addressing these issues promptly prevents more extensive and expensive damage.

Can failed concrete be repaired, or does it need complete replacement?

This depends on the extent and type of failure. Minor surface cracks and small settled sections can often be repaired effectively. However, widespread cracking, significant settling, or structural failure typically requires complete removal and replacement to ensure long-term performance.

How thick should my concrete driveway be?

Standard residential driveways handling passenger vehicles should be at least 4 inches thick. If you regularly park RVs, boats, or heavy trucks, increasing thickness to 5-6 inches provides better load distribution and longevity. Your contractor should recommend appropriate thickness based on your specific usage.

What's the difference between cracks and control joints?

Control joints are intentional, planned lines cut or formed into concrete to direct cracking to specific locations as the concrete naturally shrinks during curing. Random cracks that appear outside control joints typically indicate problems with installation, materials, or site preparation.