Concrete Maintenance Tips to Extend Its Life in Frisco

Concrete driveways, patios, and walkways represent significant investments in your Frisco property, providing durable surfaces that enhance functionality and curb appeal for decades when properly maintained. While concrete earns its reputation for strength and longevity, Texas weather conditions including intense heat, UV radiation, occasional freezing temperatures, and heavy rainfall can accelerate deterioration without appropriate care. Understanding how to maintain your concrete surfaces through regular cleaning, timely sealing, crack prevention, and proper repairs ensures your investment continues performing beautifully for years to come.

Understanding Concrete and Climate Challenges

Concrete consists of cement, aggregates, and water that harden into solid surfaces through chemical reactions. While incredibly durable, concrete remains porous and vulnerable to specific environmental stresses common in North Texas. Frisco's climate presents unique challenges for concrete longevity. Summer temperatures regularly exceed 100 degrees Fahrenheit, causing concrete to expand during heat and contract when temperatures drop. This constant thermal cycling creates internal stresses that can lead to cracking over time. Intense UV radiation from Texas sun exposure gradually degrades concrete surfaces, breaking down sealers and causing surface chalking where cement paste weakens. This degradation allows moisture penetration that accelerates deterioration.

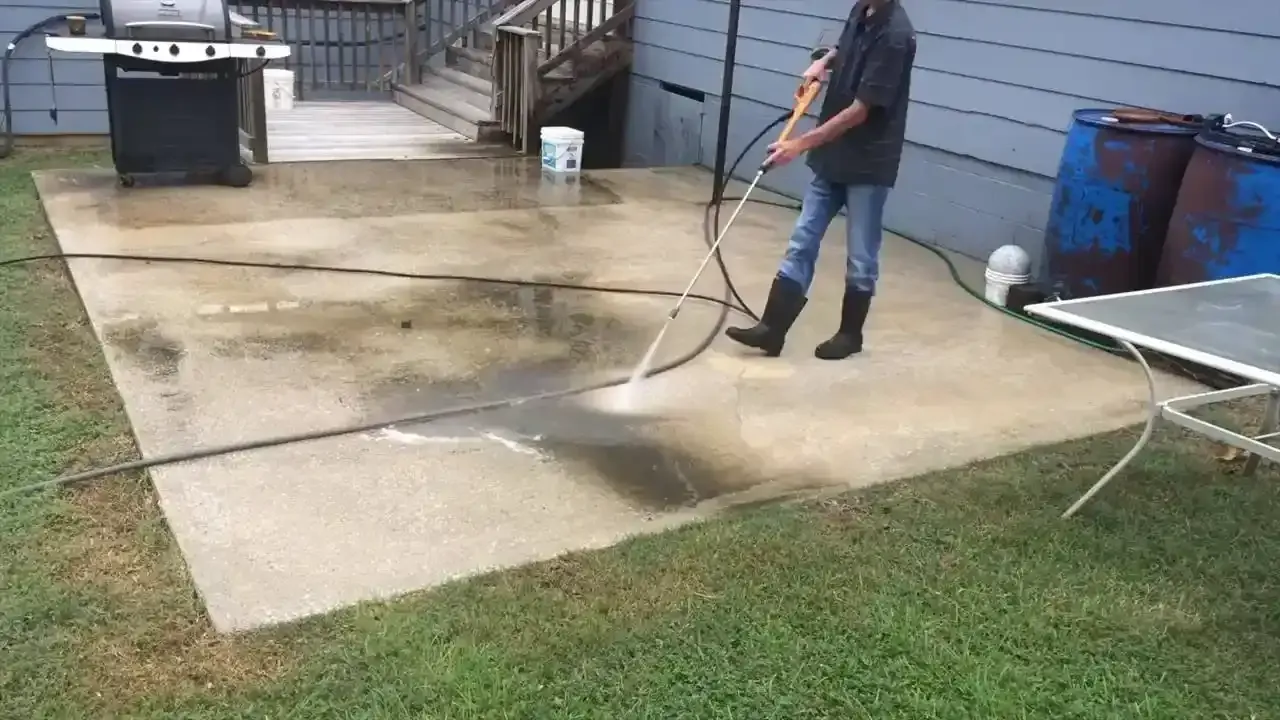

Regular Cleaning Practices

Routine cleaning represents the simplest yet most effective maintenance task for extending concrete life. Dirt, leaves, and organic debris trap moisture against concrete surfaces, creating conditions for staining, mold growth, and accelerated deterioration. Sweep concrete surfaces weekly to remove loose debris, leaves, and dirt. This basic task prevents organic material from decomposing on your concrete, which creates stains and holds moisture against the surface. Hose down concrete monthly to wash away accumulated dust, pollen, and surface contaminants. Use a regular garden hose with moderate water pressure for routine cleaning. This frequent light cleaning prevents heavy buildup requiring more aggressive methods later.

Remove oil stains using concrete degreasers or specialized oil stain removers. Apply products according to manufacturer directions, scrub with stiff brushes, and rinse thoroughly. Stubborn stains may require repeated treatments. Clean rust stains using oxalic acid-based cleaners designed for concrete. These products break down iron oxide causing rust discoloration. Always test cleaners in inconspicuous areas first to ensure they don't damage decorative finishes.

Sealing for Maximum Protection

Sealing concrete provides critical protection against moisture intrusion, staining, freeze-thaw damage, UV degradation, and surface wear. Quality sealers create barriers preventing water and contaminants from penetrating concrete while allowing vapor transmission. New concrete should be sealed after initial curing, typically 28 to 30 days after installation. This waiting period allows concrete to achieve adequate strength and dryness for proper sealer adhesion and performance. Existing concrete benefits from sealing every two to four years depending on sealer type, traffic levels, and exposure conditions. High-traffic driveways may need resealing every two years while protected patios might last four years between applications.

Acrylic sealers work well for decorative concrete including stamped and stained surfaces, enhancing colors while providing moderate protection. These sealers typically need reapplication every two to three years. Epoxy and polyurethane sealers offer maximum durability and protection, particularly for high-traffic areas. These heavy-duty sealers last longer than acrylics but cost more and require careful application. Surface preparation before sealing determines performance and longevity. Concrete must be completely clean, dry, and free from previous sealer residue, oil, grease, or contaminants. Pressure wash surfaces several days before sealing, allowing adequate drying time. Apply sealers during appropriate weather conditions with temperatures between 50 and 85 degrees Fahrenheit and no rain forecast for 24 to 48 hours. Avoid sealing in direct hot sunlight as rapid drying prevents proper penetration.

Crack Prevention and Management

Preventing cracks proves easier and less expensive than repairing them after development. Understanding crack causes helps implement preventive measures protecting your concrete investment. Control joints installed during concrete placement provide intentional weak points where concrete cracks in straight lines rather than randomly. These planned cracks should be maintained rather than filled unless they widen significantly. Proper drainage prevents water from pooling on or around concrete surfaces. Ensure concrete slopes away from buildings at minimum quarter-inch per foot grade. Clean drainage systems regularly, keeping gutters, downspouts, and yard drains flowing freely.

Never use metal shovels or sharp snow removal tools that can chip, scratch, or gouge concrete surfaces. Use plastic shovels and avoid scraping down to concrete surface when removing ice and snow. Support concrete edges properly to prevent cracking from settlement or erosion. Fill any voids that develop under concrete slabs before they cause unsupported areas that crack under load. Inspect concrete surfaces seasonally for developing cracks, surface deterioration, or drainage problems. Early detection allows minor repairs before small issues become major problems.

Crack Repair Techniques

Addressing cracks promptly prevents them from widening and water from penetrating deeper into concrete. Small crack repairs are straightforward while large or structural cracks require professional evaluation. Clean cracks thoroughly before attempting repairs. Use wire brushes, shop vacuums, or compressed air to remove loose material, dirt, and debris. Proper cleaning ensures repair materials bond effectively. Fill hairline cracks (less than one-eighth inch wide) using liquid concrete crack fillers or flexible concrete caulks designed for crack repair. These products flow into narrow cracks and remain flexible, accommodating minor concrete movement. Repair wider cracks using concrete patching compounds or polymer-modified repair mortars. Clean cracks, apply bonding agent if recommended, and pack repair material firmly into cracks. Smooth surfaces flush with surrounding concrete.

Stain Prevention Strategies

Preventing stains proves easier than removing them after they set. Understanding common staining sources helps protect your concrete from discoloration. Use drip pans under vehicles parked on driveways to catch oil, transmission fluid, and other automotive fluid leaks. These petroleum products quickly stain concrete and become difficult to remove. Move plant containers periodically to prevent moisture and organic staining from developing underneath. Use plant saucers with proper drainage and avoid leaving containers in same spots for extended periods.

Apply stain-resistant sealers providing enhanced protection against oil, grease, and other common staining agents. These specialty sealers offer superior stain resistance for high-risk areas. Clean fertilizer spills immediately as some fertilizers contain metals causing rust stains. Water affected areas thoroughly to dilute and rinse away fertilizer before it can react with concrete.

Professional Maintenance Services

While homeowners can handle routine maintenance, some situations benefit from professional concrete services. Recognizing when to call experts saves time and ensures quality results. Deep cleaning and stain removal for stubborn discoloration often requires professional equipment and expertise. Commercial pressure washing equipment and specialized stain removers achieve results homeowners cannot match. Concrete restoration including resurfacing, overlay installation, or decorative concrete application requires professional skills and equipment. These services transform worn concrete into attractive surfaces without complete replacement costs.

Structural repairs for significant cracking, settlement, or failing concrete demand professional assessment and repair. Concrete contractors identify underlying causes and implement appropriate solutions preventing recurring problems. Steadfast Concrete provides comprehensive concrete maintenance, repair, and restoration services for Frisco homeowners. Our experienced team assesses concrete condition, recommends appropriate maintenance plans, and performs repairs ensuring your concrete surfaces remain beautiful and functional.

Conclusion

Proper concrete maintenance significantly extends the life of your Frisco driveways, patios, and walkways while preserving their appearance and functionality. Regular cleaning, timely sealing, prompt crack repair, and appropriate seasonal care protect concrete from Texas weather challenges. Understanding maintenance requirements and implementing systematic care routines prevents premature deterioration while minimizing long-term costs. The time and modest expense invested in concrete maintenance pays substantial dividends through extended lifespan and enhanced property value.

Contact Steadfast Concrete at (214) 833-6372 for professional concrete maintenance, cleaning, sealing, or repair services. Our team helps Frisco homeowners protect their concrete investments through expert care ensuring beautiful, durable surfaces for years to come.