Common Differences Between Cement and Concrete

Many homeowners use the terms cement and concrete interchangeably, but these materials are distinctly different. Understanding the differences between cement and concrete helps you make informed decisions about your construction projects and communicate effectively with contractors. Whether you're planning a driveway installation or patio renovation in Frisco, knowing these key distinctions ensures better project outcomes.

What Is Cement?

Cement is a binding agent used as an ingredient in concrete. Think of it as the glue that holds concrete together. The most common type is Portland cement, made from limestone, clay, shells, and silica sand heated to extremely high temperatures. This process creates a fine powder that, when mixed with water, forms a paste that hardens over time. Cement alone is rarely used in construction projects. Its primary purpose is to bind other materials together. When water activates cement, it undergoes a chemical reaction called hydration, creating the adhesive properties necessary for construction applications.

What Is Concrete?

Concrete is a composite material that includes cement as one of its key ingredients. A typical concrete mixture contains cement, water, sand, and aggregate materials like gravel or crushed stone. The cement acts as the binder, while the aggregates provide strength, bulk, and durability. The proportions of these ingredients determine concrete's final characteristics. More cement creates stronger concrete but increases cost. Larger aggregates reduce expense while maintaining structural integrity for many applications. Water content affects workability and curing time.

Key Differences Explained

The fundamental difference is that cement is an ingredient, while concrete is the finished product. You cannot build a driveway or patio with cement alone, but you can with concrete that contains cement. Cement by itself has limited structural applications. Without aggregates to provide bulk and strength, pure cement would be prohibitively expensive and prone to excessive shrinkage and cracking. Concrete's combination of materials creates a superior building product that outperforms its individual components.

Another critical difference lies in strength development. Cement provides the binding capability, but concrete's strength comes from the entire mixture working together. The aggregates bear loads, while the cement paste binds everything into a solid mass. This combination creates the compressive strength that makes concrete ideal for foundations, slabs, and structural elements.

Composition and Ingredients

Cement contains limestone, calcium, silicon, iron, and aluminum compounds. Manufacturing requires heating these materials to create chemical bonds that activate when water is added. Different cement types serve specific purposes, with Portland cement being most common for general construction.

Concrete's composition is more complex. Beyond cement and water, it includes fine aggregates like sand and coarse aggregates such as gravel or crushed stone. The ratio typically follows general guidelines, but specific applications require adjusted proportions. Additional additives can modify characteristics like setting time, workability, or freeze-thaw resistance.

Applications and Uses

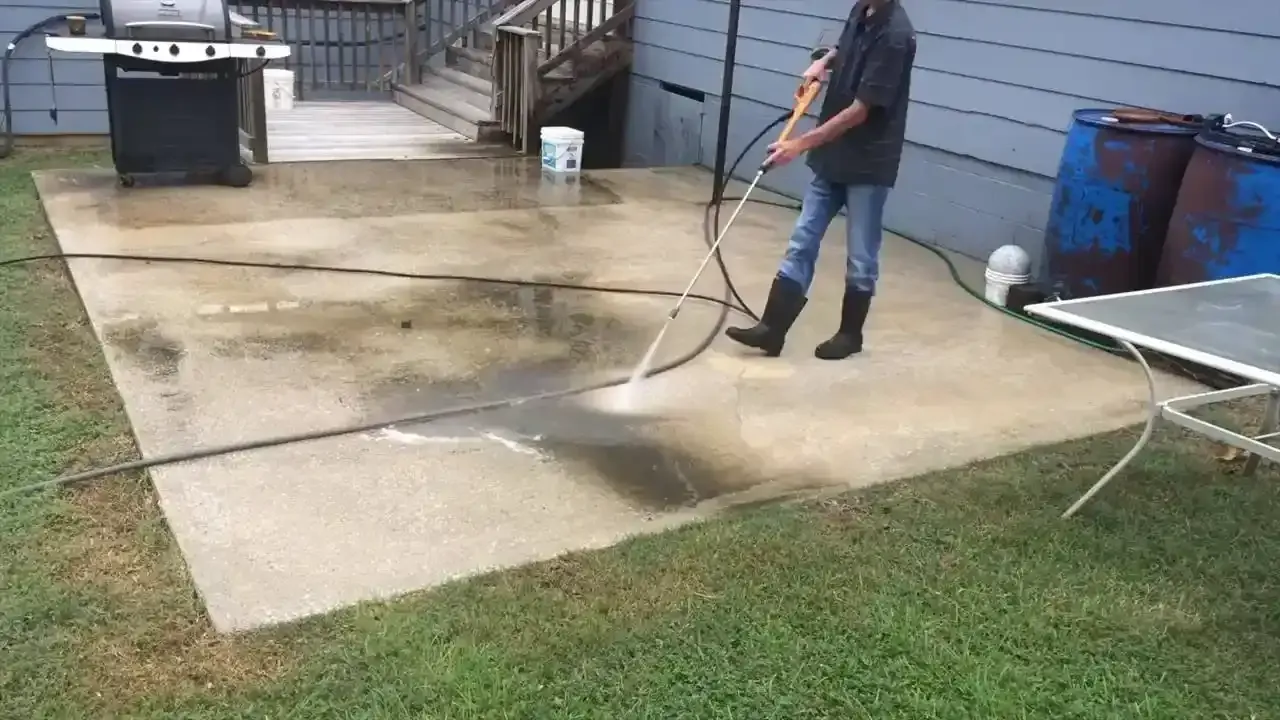

Cement's primary application is as an ingredient in other products. Beyond concrete, cement is used in mortar for masonry work, grout for tile installations, and various specialized construction applications. Some repairs use pure cement mixed with water, but these represent limited use cases. Concrete dominates construction applications. Driveways, patios, sidewalks, foundations, retaining walls, and countless other structures rely on concrete's strength and durability. Its ability to be poured, stamped, colored, and finished in numerous ways makes it incredibly versatile.

For homeowners in Frisco planning outdoor improvements, concrete offers far more possibilities than cement alone. Whether you're installing a new driveway, creating an entertainment patio, or building a pool deck, concrete provides the performance characteristics necessary for long-lasting results.

Strength and Durability

Cement paste achieves significant strength when properly hydrated, but it cannot match concrete's structural capabilities. Pure cement is prone to shrinkage cracking and lacks the bulk necessary for most construction applications. Concrete's strength develops from the synergy of its components. The cement paste binds aggregates into a monolithic structure capable of bearing substantial loads. Properly mixed and cured concrete can last decades with minimal maintenance, withstanding weather, traffic, and structural demands.

Durability differences are substantial. Cement exposed to elements without protective aggregates deteriorates faster than concrete. The aggregates in concrete protect cement paste from direct exposure while contributing to overall structural integrity. This combination resists weathering, chemical exposure, and physical wear far better than cement alone.

Curing and Setting

Both cement and concrete require proper curing, but the processes differ. Cement paste sets relatively quickly when mixed with water, beginning to harden within hours. However, this rapid setting limits workability and practical applications. Concrete's curing timeline extends longer, typically reaching initial set within several hours but requiring days or weeks to achieve full strength. The larger mass and aggregate content slow the hydration process, allowing time for proper placement and finishing. This extended curing period actually benefits final strength, as slower hydration creates more durable chemical bonds.

Professional installation ensures proper curing regardless of material. Steadfast Concrete follows proven curing protocols that account for local climate conditions, ensuring your concrete projects achieve maximum strength and longevity.

Environmental Considerations

Cement production generates significant carbon emissions due to the high temperatures required in manufacturing. This environmental impact has spurred research into more sustainable alternatives and production methods. Concrete's environmental footprint includes cement production but is offset by concrete's longevity and recyclability. Properly installed concrete lasts decades, reducing the need for replacement and associated environmental costs. Crushed concrete can be recycled as aggregate for new projects, reducing waste and resource consumption.

Making the Right Choice

For virtually all residential and commercial construction projects, concrete is the appropriate choice. Its combination of strength, durability, versatility, and cost-effectiveness makes it ideal for driveways, patios, walkways, and structural applications. Understanding that cement is simply one ingredient in concrete helps you communicate more effectively with contractors and make informed decisions about your projects. When discussing your Frisco home improvement plans, you'll be specifying concrete work, not cement work.

Professional contractors provide guidance on the specific concrete mixture best suited for your application, considering factors like intended use, climate exposure, aesthetic preferences, and budget. This expertise ensures your project delivers the performance and appearance you expect. Whether you're planning a small patio or extensive driveway installation, knowing the difference between cement and concrete demonstrates informed decision-making and helps ensure successful project outcomes that enhance your property for years to come.